It’s a made-in-Saskatchewan success story.

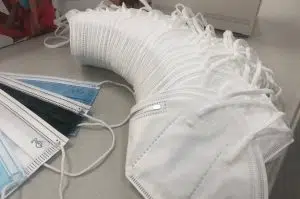

A Saskatoon company that makes medical grade personal protective equipment (PPE) is expanding, after demand for its products significantly increased.

Justin Stuart, who co-owns Benchmark PPE with Olga Bugrova, has secured a Saskatchewan government ministry contract to provide millions of masks for schools across the province. While Stuart can’t get into too many details, he says he’s proud and grateful to be able to do the work.

“We’re very lucky,” he says. “Our business is expanding because we’ve stuck with the production. We’ve achieved a high level of quality through hard, hard work, and we’re very fortunate that we’ve had some good partners that have come forward and given us purchase orders for our products.

“We’re very, very, very grateful to have the opportunity to be supplying something as important as the schools. I mean, let’s face it: If you’re looking at an opportunity, what is more important than giving PPE to the children who are going to school? … That’s the highest level of trust, and we’re very proud of that.”

But it hasn’t been easy for Stuart and Bugrova, who currently employ about 30 people. The company started about five years ago, making engineered products for the oil and gas, mining and construction sectors.

That all changed when the pandemic hit.

“When COVID hit hard, our business went down about 95 per cent and we started to look at other opportunities and we decided to pivot into making PPE specifically masks, bouffant caps and sanitizing wipes,” Stuart says.

They purchased equipment from China, learned how to use it all, and got a medical device establishment licence. All of their products are Health Canada-certified, including the N95-level equivalent masks.

“(The National Institute for Occupational Safety and Health) is American. Canada doesn’t have its own network yet,” Stuart says. “So what happened is we made our respirator, we sent it off to (the National Research Council), they tested it, and our mask meets or exceeds the N95-level requirements.”

While Stuart says the company has applied to the U.S. for NIOSH approval, American companies are being prioritized first, and it takes 18 months to get that approval. In the meantime, his company is rigorously following Health Canada guidelines.

He says in addition to the new Saskatchewan ministry contract, Benchmark also supplies PPE to mining and construction companies across the country, and to the general public. It’s looking for new contracts as well, but hasn’t had success yet with the Saskatchewan Health Authority (SHA).

“I personally think it’s been difficult for us to supply to the SHA because pre-pandemic, the SHA had a buying model that was using a group purchasing strategy and also using the federal government as an assist to get what they needed …,” Stuart says.

“It’s nothing intentional, it’s that they’re overworked and they still don’t have the framework in place to allow them to work outside the existing procurement network.”

Stuart does believe local or provincial companies should have more of a chance to bid on contracts and to supply goods and services with large buying organizations, but they often don’t have a chance to do that.

With the new government contract, Benchmark is moving from a total of 7,000 square feet to a facility that will be nearly 15,000 square feet. Right now, the company can produce about 150,000 three-ply medical grade masks, and 25,000 N95-level masks every day. By February, it’ll be able to produce 50,000 N95 respirators per day.

Stuart and Bugrova also hope Benchmark will become the first company in Canada to produce nitrile gloves used in hospitals, autobody shops, painting companies and others. They’ve even bid on a federal government 10-year contract, and are waiting to see what happens.

“That’s a great example of where we want to go as a company because nitrile gloves were used before the pandemic,” Stuart says. “They’re going to get used after the pandemic. They’re certainly in high demand.”

And, as more people learn about their business, the more people are ordering local products.

Post-pandemic, he hopes the jobs Benchmark has created will remain, and it’ll continue to provide materials for companies across the country. For more information on the products, go to the company’s website.